How Is Paper Made

The Diamond Sutra of the, the oldest dated printed book in the world, found at, from 868 CE. The art, science, and technology of papermaking addresses the methods, equipment, and materials used to make and, these being used widely for printing, writing, and packaging, among many other purposes and useful products. Today almost all paper is, while handmade paper survives as a specialized craft and a medium for. In papermaking, a dilute suspension consisting mostly of separate cellulose fibres in water is drained through a sieve-like screen, so that a mat of randomly interwoven fibres is laid down. Water is further removed from this sheet by pressing, sometimes aided by suction or vacuum, or heating.

Once dry, a generally flat, uniform and strong sheet of paper is achieved. Before the invention and current widespread adoption of automated machinery, all paper was made by hand, formed or laid one sheet at a time by specialized laborers. Even today those who make paper by hand use tools and technologies quite similar to those existing hundreds of years ago, as originally developed in China and Asia, or those further modified in Europe. Handmade paper is still appreciated for its distinctive uniqueness and the skilled craft involved in making each sheet, in contrast with the higher degree of uniformity and perfection at lower prices achieved among industrial products. While monitoring, regulations and action by concerned citizens, as well as improvements within the industry itself are limiting the worst abuses, papermaking continues to be of, due to its use of harsh chemicals, its need for large amounts of water, and the resulting contamination risks, as well as trees being used as the primary source of. Paper made from other fibers, cotton being the most common, tends to be valued higher than wood-based paper.

An 18th-century Qing dynasty print depicting, who is traditionally attributed as the inventor of papermaking. Papermaking is traced back to about 105 CE, when, an official attached to the Imperial court during the (202 BCE-220 CE), created a sheet of paper using and other along with fishnets, old rags, and waste. Paper with legible Chinese writings on it dating from 8 BCE, while hempen paper had been used in for wrapping and padding since the eighth century BCE. Paper used as a writing medium became widespread by the 3rd century and, by the 6th century, was starting to be used in China as well. During the (618-907 CE) paper was folded and sewn into square to preserve the flavour of tea, while the later (960-1279 CE) was the first government to issue paper-printed money. In the 8th century, papermaking spread to the, where the process was refined, and machinery was designed for bulk manufacturing. Production began in, and then.

For years, natural trees have been used to make tissue paper, but the nanotechnology industry has been working to produce genetically modified trees, which produce a new type of tissue paper that has a higher quality. These man-made trees produce what is called 'intelligent wood.' This new class of. Formed from wood pulp or plant fiber, paper is chiefly used for written communication. The earliest paper was papyrus, made from reeds by the ancient Egyptians. Paper was made by the Chinese in the second century, probably by a Chinese court official named Cai Lun. His paper was made from such things as tree bark.

In, papermaking was under the supervision of the. Muslims invented a method to make a thicker sheet of paper. This innovation helped transform papermaking from an art into a major industry. The earliest use of in paper production, specifically the use of for preparing the pulp for papermaking, dates back to in the 8th century. The earliest references to also come from the, where they were first noted in the 9th century by in. Papermaking was diffused across the Islamic world, from where it was diffused further west into.

Traditional uses the inner bark fibers of plants. This fiber is soaked, cooked, rinsed and traditionally hand-beaten to form the paper pulp. The long fibers are layered to form strong, translucent sheets of paper. Three traditional fibers are, and. Today, this paper is used for calligraphy, printing, book arts, and three-dimensional work, including. Modern papermaking began in the early 19th century in with the development of the.

This machine produces a continuous roll of paper rather than individual sheets. These machines are large.

Some produce paper 150 meters in length and 10 meters wide. They can produce paper at a rate of 100 km/h.

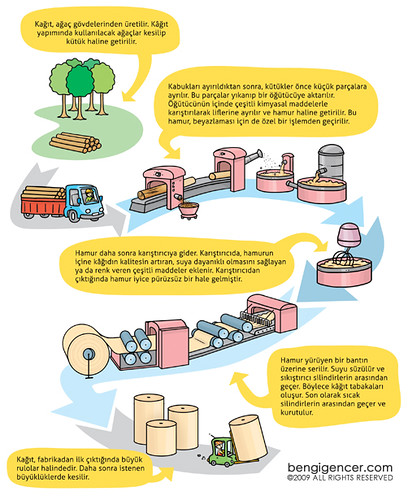

In 1844, and German had invented the machine and associated process to make use of wood pulp in papermaking. This innovation ended the nearly 2,000-year use of pulped rags and start a new era for the production of and eventually almost all paper was made out of pulped wood. Manual papermaking. Five seminal steps in ancient papermaking outlined in a. Papermaking, regardless of the scale on which it is done, involves making a dilute suspension of in water, called 'furnish', and forcing this suspension to drain through a screen, to produce a mat of interwoven fibres.

Water is removed from this mat of fibres using a press. The method of manual papermaking changed very little over time, despite advances in technologies. The process of manufacturing handmade paper can be generalized into five steps:.

Separating the useful fibre from the rest of raw materials. Cellulose from wood, cotton, etc.).

Beating down the fibre into pulp. Adjusting the colour, mechanical, chemical, biological, and other properties of the paper by adding special chemical premixes. Screening the resulting solution. Pressing and drying to get the actual paper Screening the fibre involves using a mesh made from non-corroding and inert material, such as aluminium, which is stretched in a wooden frame similar to that of a window. The size of the paper is governed by the size of the frame.

This tool is then completely submerged in the solution vertically and drawn out horizontally to ensure a uniform coating of the wire mesh. Excess water is then removed and the wet mat of fibre laid on top of a damp cloth. The process is repeated for the required number of sheets.

This stack of wet mats is then pressed in a hydraulic press very gently to ensure the fibre does not squeeze out. The fairly damp fibre is then dried using a variety of methods, such as vacuum drying or simply air drying. Sometimes, the individual sheet is rolled to flatten, harden, and refine the surface. Finally, the paper is then cut to the desired shape or the standard shape (A4, letter, legal, etc.) and packed. The wooden frame is called a '. The deckle leaves the edges of the paper slightly irregular and wavy, called 'deckle edges', one of the indications that the paper was made by hand. Deckle-edged paper is occasionally mechanically imitated today to create the impression of old-fashioned luxury.

The impressions in paper caused by the wires in the screen that run sideways are called 'laid lines' and the impressions made, usually from top to bottom, by the wires holding the sideways wires together are called 'chain lines'. Are created by weaving a design into the wires in the mould. Handmade paper generally folds and tears more evenly along the laid lines.

How Is Paper Made Kids

Handmade paper is also prepared in laboratories to study papermaking and in paper mills to check the quality of the production process. The 'handsheets' made according to Standard T 205 are circular sheets 15.9 cm (6.25 in) in diameter and are tested for paper characteristics such as brightness, strength and degree of sizing. Industrial papermaking.

See also: and A modern paper mill is divided into several sections, roughly corresponding to the processes involved in making handmade paper. Pulp is refined and mixed in water with other additives to make a pulp slurry. The head-box of the paper machine (Fourdrinier machine) distributes the slurry onto a moving continuous screen, water drains from the slurry (by gravity or under vacuum), the wet paper sheet goes through presses and dries, and finally rolls into large rolls. The outcome often weighs several tons. Another type of paper machine makes use of a cylinder that rotates while partially immersed in a vat of dilute pulp. The pulp is picked up by the wire and covers the mould as it rises out of the vat. A couch roller is pressed against the mould to smooth out the pulp, and picks the wet sheet off the mould.

Notable papermakers. Main page: While papermaking was considered a lifework, exclusive profession for most of its history, the term 'notable papermakers' is often not strictly limited to those who actually make paper. Especially in the hand papermaking field there is currently an overlap of certain celebrated paper art practitioners with their other artistic pursuits, while in academia the term may be applied to those conducting research, education, or conservation of books and paper artifacts. In the industrial field it tends to overlap with science, technology and engineering, and often with management of the pulp and paper business itself. Some well known and recognized papermakers have found fame in other fields, to the point that their papermaking background is almost forgotten. One of the most notable examples might be that of the first humans that achieved flight, the, where many accounts barely mention the paper mill their family owned, although paper used in their balloons did play a relevant role in their success, as probably did their familiarity with this light and strong material. Key inventors include, and, among others.

Paper sizes.